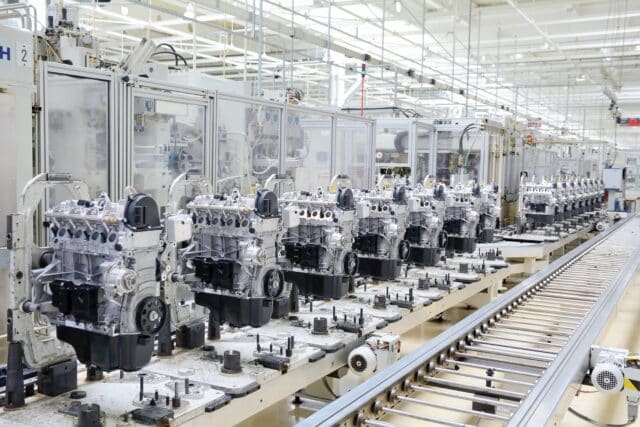

Petrochemical

Comprehensive and innovative solutions to complex issues.

Learn MoreMSB is a leader in the field of electrical engineering. Our team is highly experienced in performing electrical analysis, reliability improvements, equipment retrofits and grassroots designs for various industries across the United States, including refineries, chemical plants, terminal/storage sites and pipeline facilities. With a long history of handling complex and time-sensitive projects, we serve our clients’ needs in an efficient manner, always maintaining our focus on industry standards for reliability and safety.

We solve electrical power system challenges for clients in a variety of industries.

Capital expansion, maintenance of systems and general infrastructure improvements.

Learn More

We provide solutions to expand operations, upgrade systems, and control costs.

Learn More

We help our clients safely improve efficiency, meet financial goals, and work toward the next generation of energy.

Learn More

Our engineers provide detailed engineering and design of electrical power distribution systems, electrical system analyses, utility power acquisition, troubleshooting and technical support. From initial estimation and specifications to final commissioning and ongoing support, MSB delivers turnkey solutions to clients.

At MSB, we believe that all workplace incidents are preventable. We make it our mission to prove that by providing high-quality safety programs that empower employees to help make it possible.

Learn More