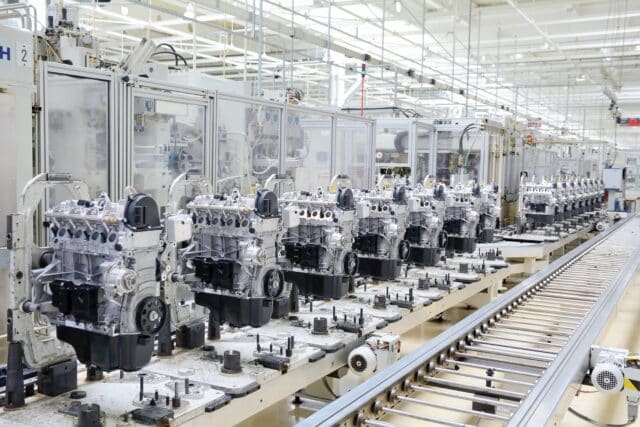

Petrochemical

Comprehensive and innovative solutions to complex issues.

Learn MoreAt M S Benbow, we understand the high stakes of maintaining operational efficiency and respond swiftly and strategically to disruptions in your instrumentation and control systems. Our seasoned team of experts is committed to diagnosing issues, proposing practical solutions, and rapidly mobilizing the necessary equipment and expertise. We offer instant proficiency in a field where experienced professionals are hard to find, ensuring a seamless process without a costly learning curve.

We solve instrumentation and control challenges for clients in a variety of industries.

Capital expansion, maintenance of systems and general infrastructure improvements.

Learn More

We provide solutions to expand operations, upgrade systems, and control costs.

Learn More

We help our clients safely improve efficiency, meet financial goals, and work toward the next generation of energy.

Learn More

Striking a balance between progressive growth and dealing with faltering or obsolete equipment can be tough. Our engineers and control system specialists help you navigate this challenge by offering unbiased, effective solutions that align with your business goals. When it comes to upgrading your systems, we follow a disciplined and reliable design process to ensure success. Acting as an extension of your team, we guide you through conception, design, installation, testing, and implementation.

At MSB, we believe that all workplace incidents are preventable. We make it our mission to prove that by providing high-quality safety programs that empower employees to help make it possible.

Learn More